Prioritize Outbound Inspections Using Rules Engine and Machine Learning

You have been able to inspect picked sales order lines since the introduction of the Verify Pick feature in Release 12.2.9. You could use your own custom extension to identify LPNs for inspection to verify the items and quantities that were picked. In Release 12.2.15, you can use the rules engine and machine learning to identify sales order lines for inspection. You can use the rules engine to specify inspection criteria, like user, customer, or item, to identify LPNs for inspection, eliminating the need for a custom extension. Additionally, you may choose to use machine learning to calculate a discrepancy probability for each line by analyzing various data sources, like RMAs, cycle count discrepancies, and past inspection results. You can define a rule which compares the discrepancy probability to a threshold value as a part of determining which lines to inspect. For example, with machine learning and the rules engine, you can ensure that a high value item for a key customer is inspected if the discrepancy probability is greater than 3%.

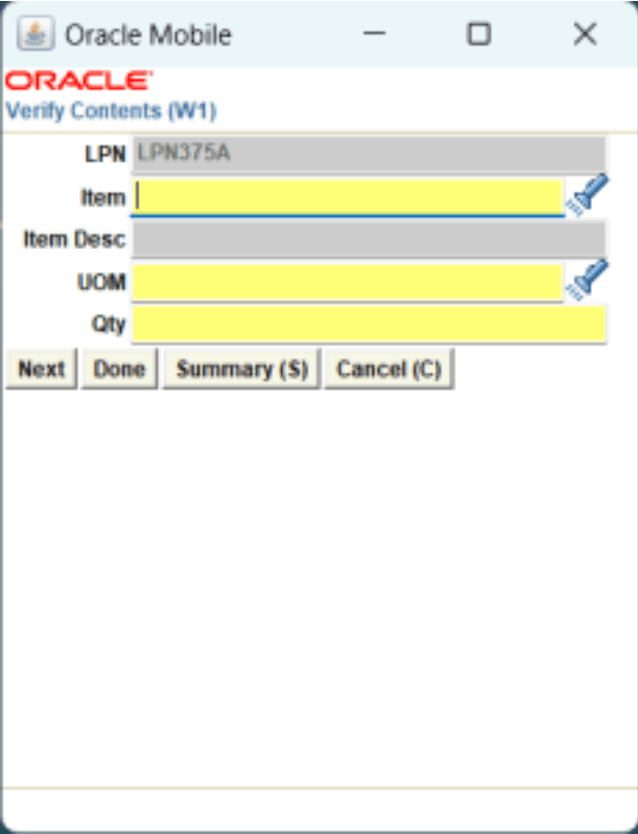

A new concurrent program named 'Pregenerate Pick Verification Suggestions' is automatically launched during Pick Release and when Warehouse Control Board updates tasks. It calls the Pick Verification rules to identify which tasks are marked for pick verification. The Verify Contents mobile page has been modified so that the Item field now supports a list of values (LOV). This Item LOV contains the list of items present in the LPN that are marked for verification. You can still enter and verify an item that is not marked for verification. In this case, system will display a warning message that "This item is not marked for pick verification." If you verify an item that is not marked for verification, then upon completing the verification, this item will be marked for verification.

New Verify Contents Mobile Page

There are 2 significant benefits. The first advantage is convenience. Using the rules engine to determine which sales order lines to schedule for inspection is faster and much more convenient than writing code for a custom hook. Given the added convenience and flexibility, it's likely that more lines will be inspected and fewer items will be returned. The second advantage is the ability to harness the power of machine learning. Users can now leverage a model's insights when determining which lines to inspect. Augmenting your knowledge with insights from machine learning, should lead to even better outcomes over time.

Steps to Enable

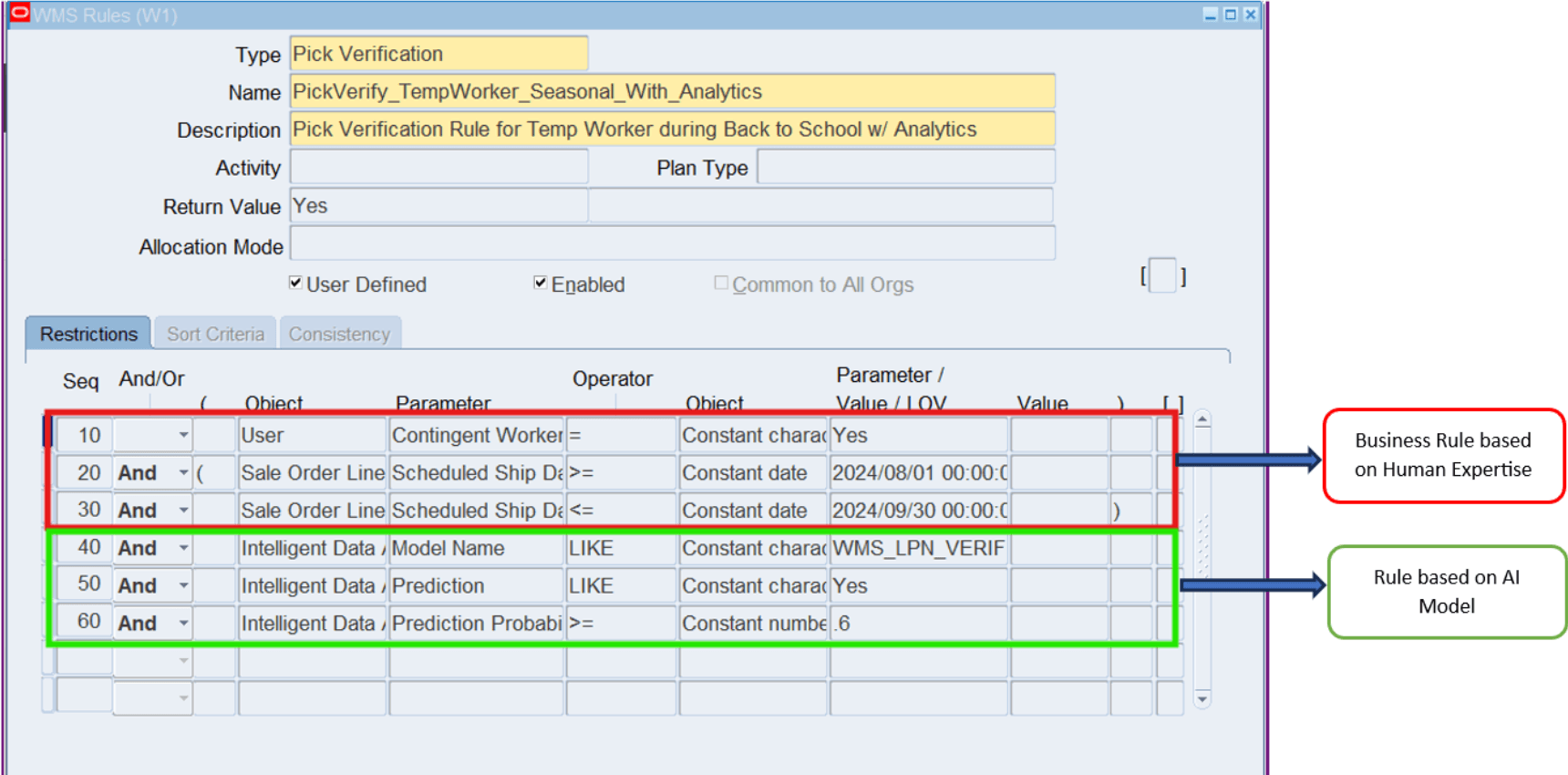

To enable this feature you must define and enable a Pick Verification rule. Pick Verification is a new rule type introduced in Release 12.2.15. You can setup the rule to specify which lines require inspection by selecting attributes from existing objects, as shown in the green box below. If desired, you can also use machine learning, as shown in the red box below. The seeded model considers past data related returned material (RMAs), cycle count discrepancies, and pick verification inspection results. Using this information, the model develops a discrepancy likelihood for each line that is picked. If the discrepancy likelihood exceeds the user-provided threshold value, the LPN containing the pick will be scheduled for inspection using the pick verify feature.

Pick Verification Rule

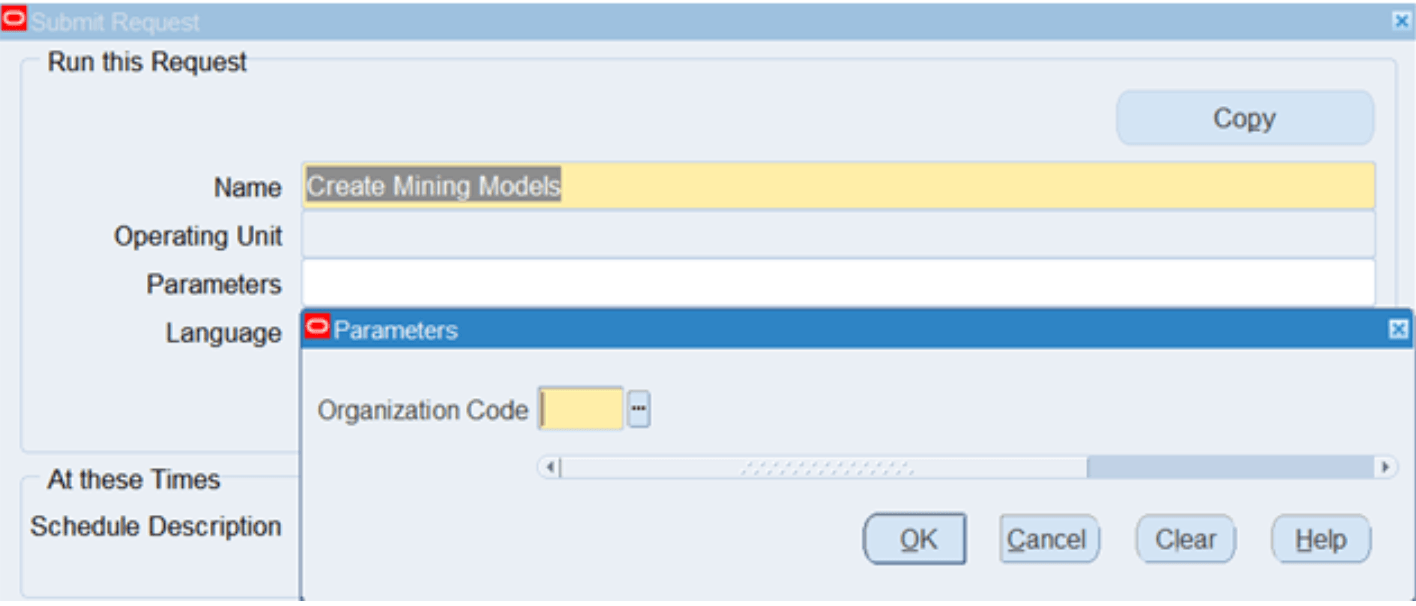

To use machine learning in the rule, the model must be created and trained. Use the following concurrent process to create and train the model:

Create Mining Models

Use the Create Mining Models program to create new and train new models and re-train existing models based on the existing data set. Each mining model created will have an entry in WMS_MINING_MODELS. Creating data mining models requires:

- A Model Name - No User Entry

- Mining Function- No User Entry

- Dataset- No User Entry

- Primary identifier column- No User Entry

- Target column- No User Entry

- Settings Table- No User Entry

- Org Code - User Entry

- Date Range - TBD if days or years - No User Entry

You can submit the "Create Mining Models" Concurrent Program from Warehouse Manager Responsibility.

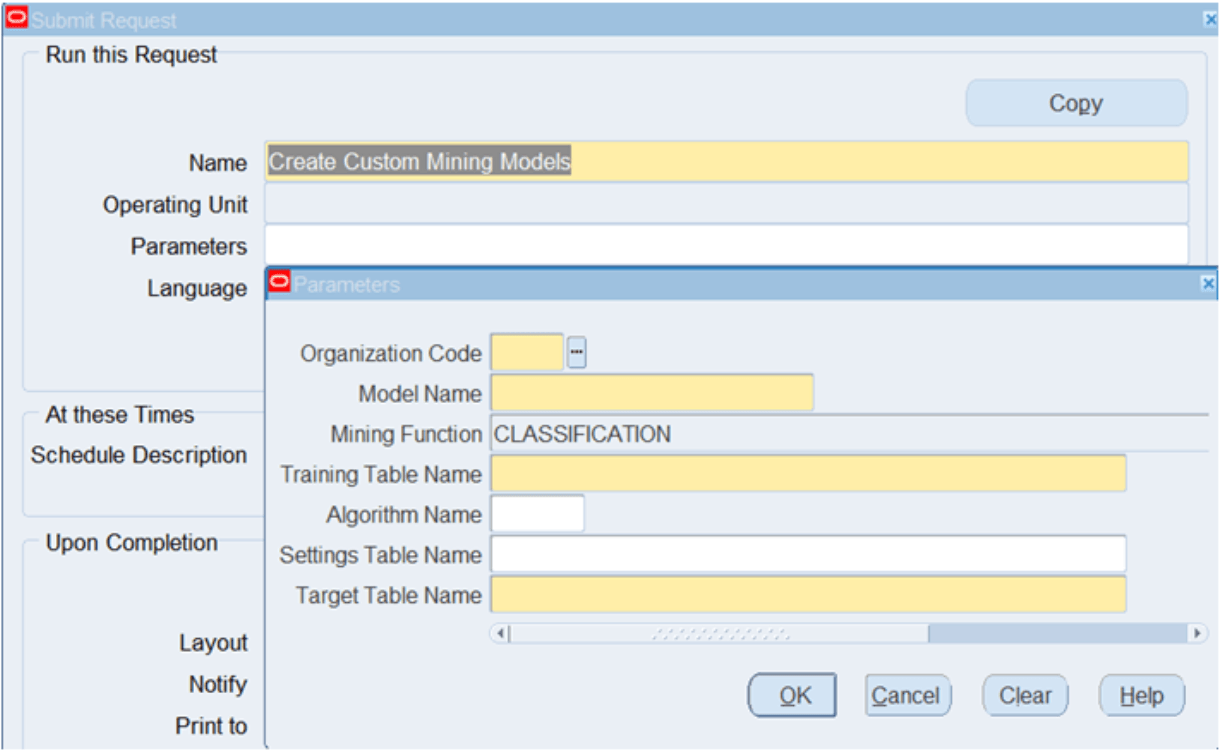

To use your own model in the rule, please use the following concurrent program to create and train a custom model:

Create Custom Mining Models

You can submit the "Create Custom Mining Models" Concurrent Program from Warehouse Manager Responsibility. You will be prompted for the following parameters.

- Organization Code - Required

- Model Name - You can enter the model Name here

- Mining Function - Non editable and defaulted to CLASSIFICATION

- Training Table Name - Required

- Algorithm Name - If you do not select the Algorithm Name, then system will create 4 models, 1 for each algorithm.

- Settings Table Name - Table/View name that contains the required settings information for the model creation

- Target Table Name - Required

Tips And Considerations

Machine learning uses models to evaluate likely outcomes. In turn, the models analyze data to identify relationships and probable outcomes.

As the data in the model changes, so too will the potential outcomes. To ensure that models are providing the best insights, they need to be trained on the latest available data on a regular schedule.

Key Resources

Oracle Warehouse Management User's Guide

- Chapter: Oracle Warehouse Management Outbound Logistics

- Topic: Pick Verification Using Machine Learning