Prioritize Cycle Counts Using Machine Learning

Cycle counts are typically scheduled based on item velocity or value. In Release 12.2.15, you can use machine learning to identify items generating an unusually high number of discrepancies. Machine learning calculates an on-hand discrepancy probability for each item in each location using historical cycle count adjustment data. You can easily visualize the most likely inventory discrepancies in the Inventory Aging Dashboard and create a cycle count schedule. This data-driven approach enhances inventory management by improving accuracy, optimizing resource allocation, and increasing cycle counting efficiency.

Steps to Enable

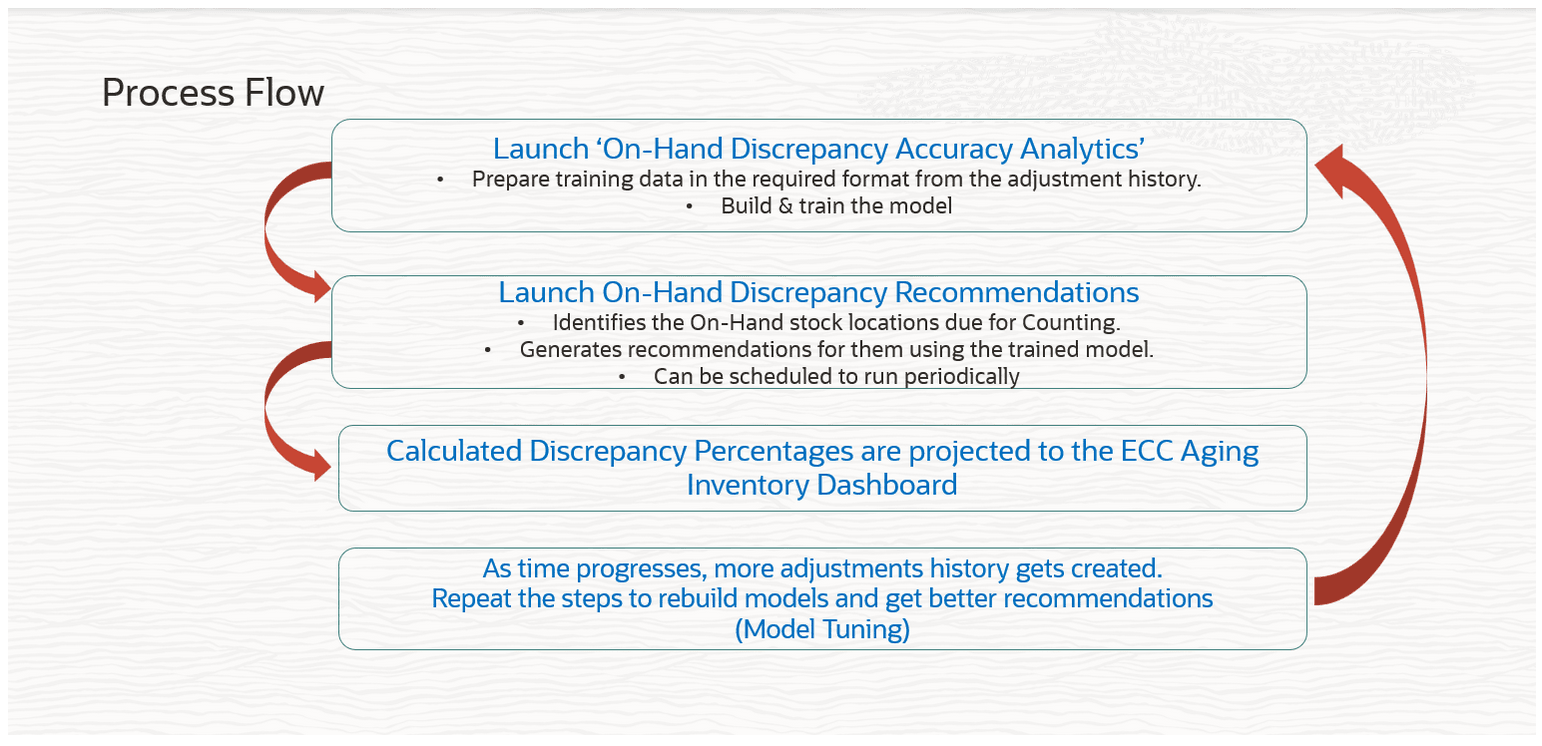

Setup Process Flow

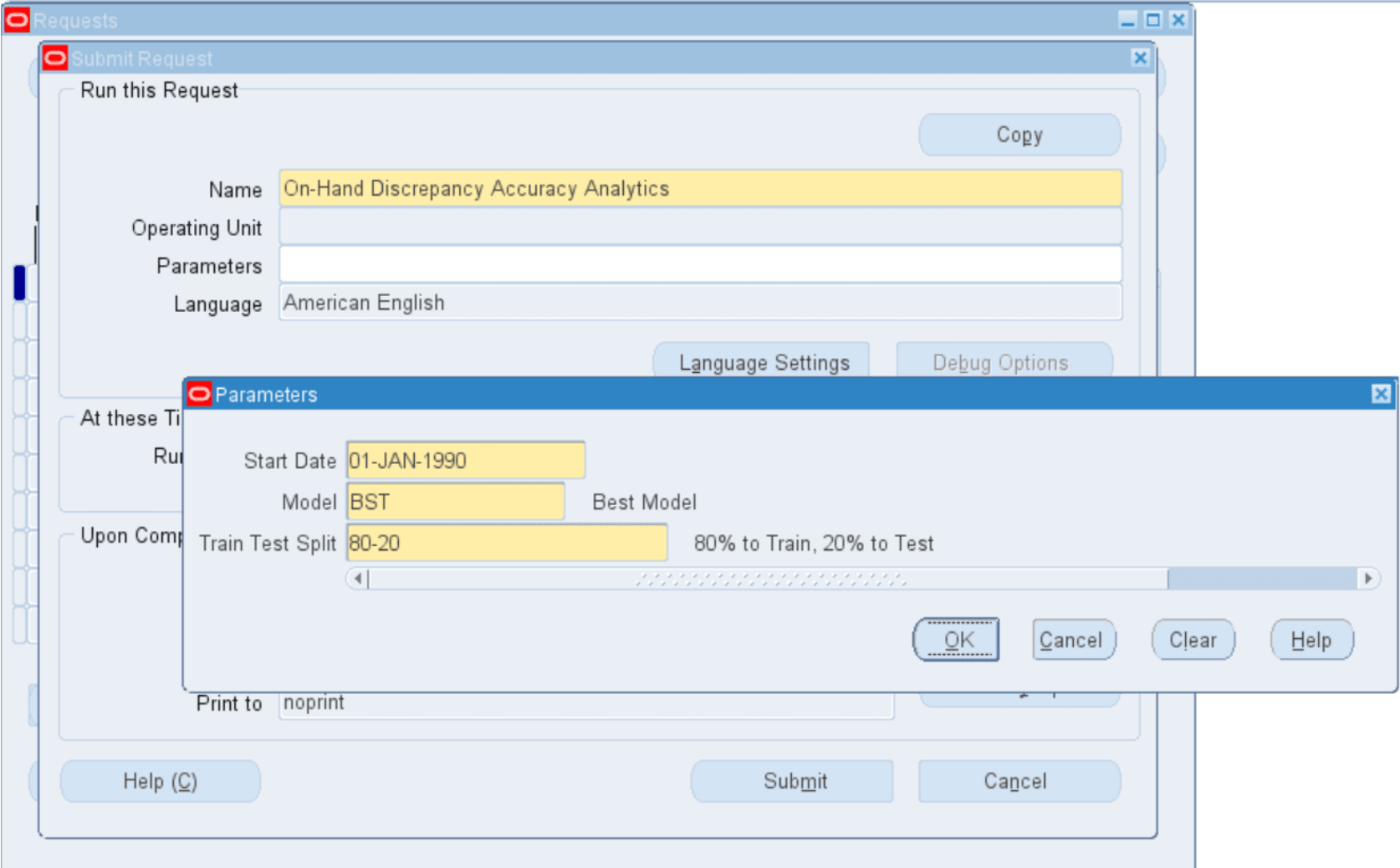

Step 1: Run On-Hand Discrepancy Accuracy Analytics program .

This program has 3 mandatory parameters:

- Start Date: Adjustment Transactions from this date onwards will be used to train the Machine Learning Model.

- Model: The Regression algorithm to be used for building the model.

- Train/Test Split: Training data to Test Data split ratio.

Ensure this program completes successfully before proceeding.

Run On-hand Discrepancy Accuracy Analytics Program

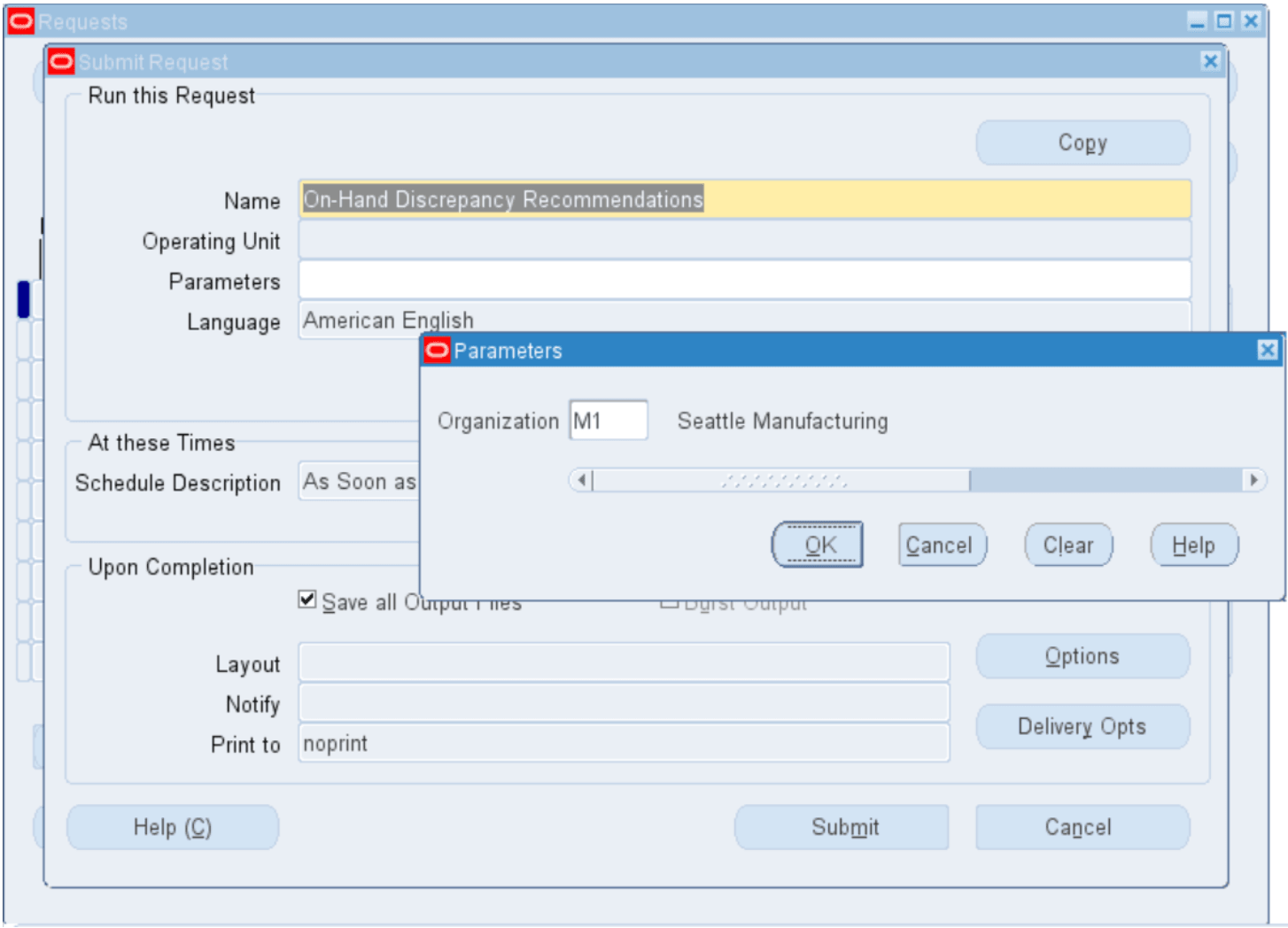

Step 2: Run On-Hand Discrepancy Recommendations program.

This program will have only one optional parameter: Organization.

Ensure this program completes successfully before proceeding.

Run On-hand Discrepancy Recommendations Program

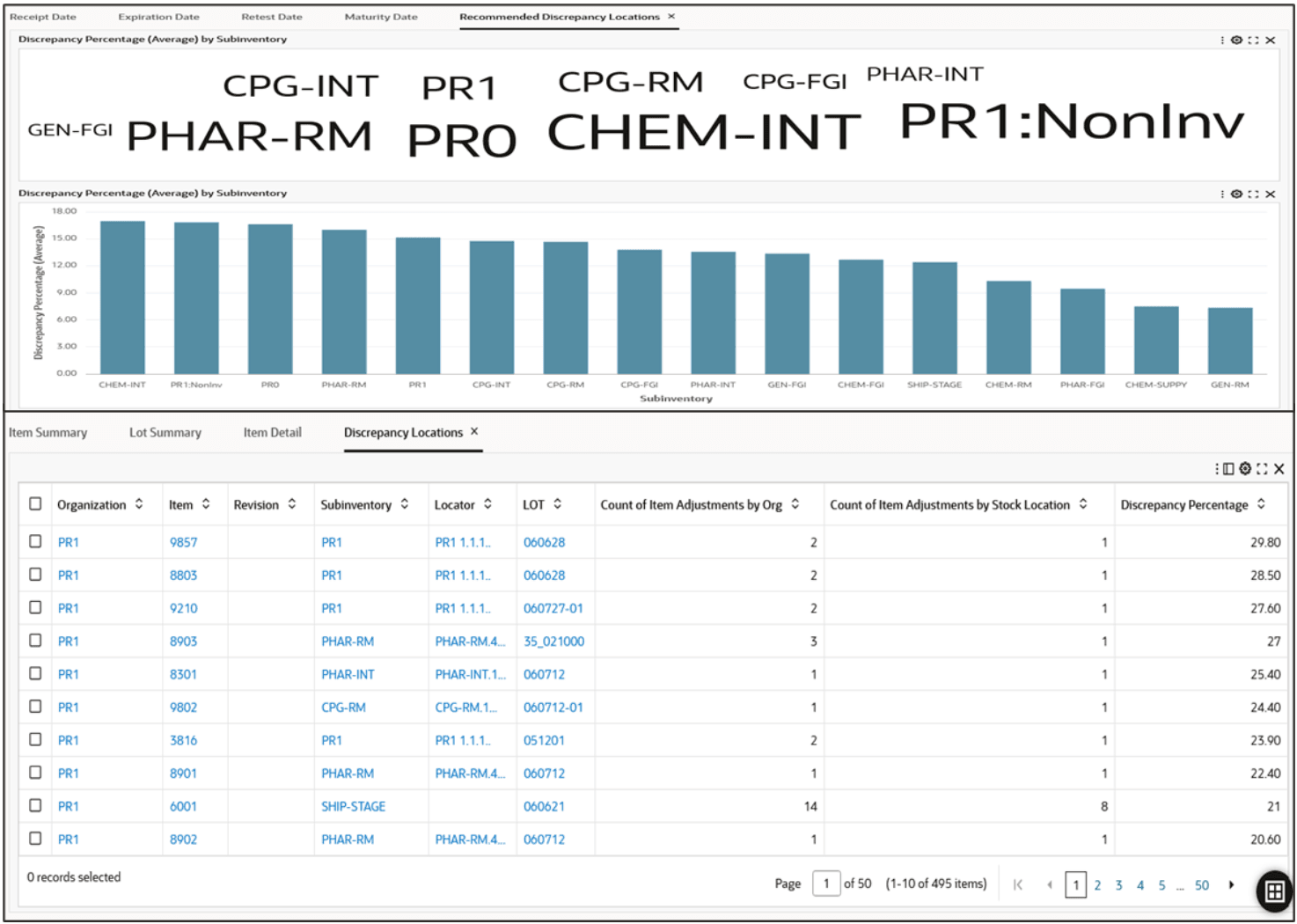

Open the Aging Dashboard (ECC) go to the Recommended Discrepancy Locations tab and view the Discrepancy Percentages.

Discrepancy Percentages in Aging Dashboard

Key Resources

- Chapter 19, Cycle Counting, section title: Prioritize Cycle Counts to Analyze Inventory Discrepancies Using Machine Learning