Use Actual Costing in Full Outsourcing Flow with Discrete Manufacturing

Discrete manufacturing organizations utilizing the full outsourcing flow can now adopt any costing method, including Standard, Average, FIFO, and LIFO. Additionally, organizations using actual costing with outsourcing can also leverage project manufacturing.

The actual costing process will automatically account for:

- The value of the subcontracting components issued by the original equipment manufacturer (OEM) to the manufacturing partners (MP) in a subcontracting in-transit account.

- The outsourced assemblies and subcontracting components which will be costed according to the assigned costing method for the organization.

- Project costing of the components and assemblies if a project / task is involved.

Prior to Release 12.2.15, you could only use standard costing for organizations that used the full outsourcing flow.

Process Flow

1. Organization Setup (MP)

- Set up External MP Simulation Organizations with the same cost method as the OEM.

- Allow costing in the simulation MP organization. As these are actual costing organizations, there are no standard costs to estimate inventory value in the MP and for other calculations. The cost processor will:

- Dynamically calculate average or layer cost of components shipped from the OEM to the MP.

- Determine assembly completion cost based on component costs and BOM in the MP.

- If the OEM is Project Manufacturing enabled, ensure the MP is also project-manufacturing enabled, to:

- Record all MP transactions for appropriate project/task.

- Enable cost calculation at project/task level.

2. Transaction Cost Flow (MP)

- The application ensures that cost information flows accurately between the OEM and the MP for actual costing.

- At Component Shipment from the OEM to the MP:

- Shipping costs of the OEM are stamped on replenishment receipts in the MP.

- Components carry the cost from the OEM to the MP.

- During Component Issue to the Work Order in the MP:

- Current re-averaged component costs in the MP are used

- These contribute to outsourced assembly's material cost.

At any point inventory and WIP in the MP reflect the actual value of components received.

3. Transaction Cost Flow (OEM)

- When Processed Assembly is Received Back in the OEM:

- Transaction cost is calculated as:

- Landed Cost = Material Cost in the MP + Value-Added Cost Charged by the MP

- Receipt is initially placed On Hold (OSM Pending) until:

- Assembly completion is performed and costed by the MP, so that the material cost is available to calculate receiving cost for the OEM.

Accounting Example

The following example illustrates how subcontracting in-transit accounting in the OEM tracks the value of subcontracted components held in the MP. It shows how the total account balance accurately represents the value of components in the MP. The actual costing process in the MP, combined with the Outsourced Manufacturing application, ensures this accuracy is maintained even in more complex scenarios.

Note: The costing and accounting of transactions in the MP are purely simulations and are not posted to the GL. Their sole purpose is to estimate actual material and assembly costs in the MP and support actual costing for Outsourced Manufacturing

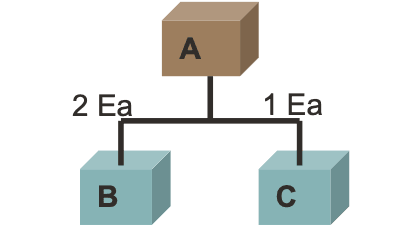

Outsourced Assembly BOM Structure

Current costs in the OEM Organization

Subcontracting Component B: $2

Subcontracting Component C: $3

Subcontracting Assembly A: Will be calculated at PO Receipt

Accounting Entries for the OEM Organization

| Transaction | Item | Qty | Price / Cost | Account | Dr | Cr |

|---|---|---|---|---|---|---|

| Ship Confirm of Replenishment Sales Orders | B | 2 | $2 | Inventory Valuation | $4 | |

| Subcontracting Intransit | $4 | |||||

| Ship Confirm of Replenishment Sales Orders | C | 1 | $3 | Inventory Valuation | $3 | |

| Subcontracting Intransit | $3 | |||||

| Receipt into Receiving Inspection of Subcontracting PO | A | 1 |

PO Price: $5 Material Cost: $7 Total Cost: $12 |

A/P Accrual | $5 | |

| Receiving Inspection | $12 | |||||

| Subcontracting Intransit | $7 | |||||

| PO Receipt of Subcontracting PO | A | 1 | Cost: $12 | Receiving Inspection | $12 | |

| Inventory Valuation | $12 |

Current costs in the OEM Organization

Subcontracting Component B: Will be calculated at PO Receipt

Subcontracting Component C: Will be calculated at PO Receipt

Subcontracting Assembly A: Will be calculated at Assembly Completion

Inventory Accounting Entries for the MP Organization (Simulation Only. Not transferred to GL)

| Transaction | Item | Qty | Price / Cost | Account | Dr | Cr |

|---|---|---|---|---|---|---|

| PO Receipt | B | 2 | $2 | Inventory Valuation | $4 | |

| Receiving Inspection | $4 | |||||

| PO Receipt | C | 1 | $3 | Inventory Valuation | $3 | |

| Receiving Inspection | $3 | |||||

| Component Issue | B | 2 | $2 | Inventory Valuation | $4 | |

| WIP Valuation | $4 | |||||

| Component Issue | C | 1 | $3 | Inventory Valuation | $3 | |

| WIP Valuation | $3 | |||||

| Assembly Completion | A | 1 | $7 | WIP Valuation | $7 | |

| Inventory Valuation | $7 |

Steps to Enable

- Set up the MP organization to not allow negative balances.

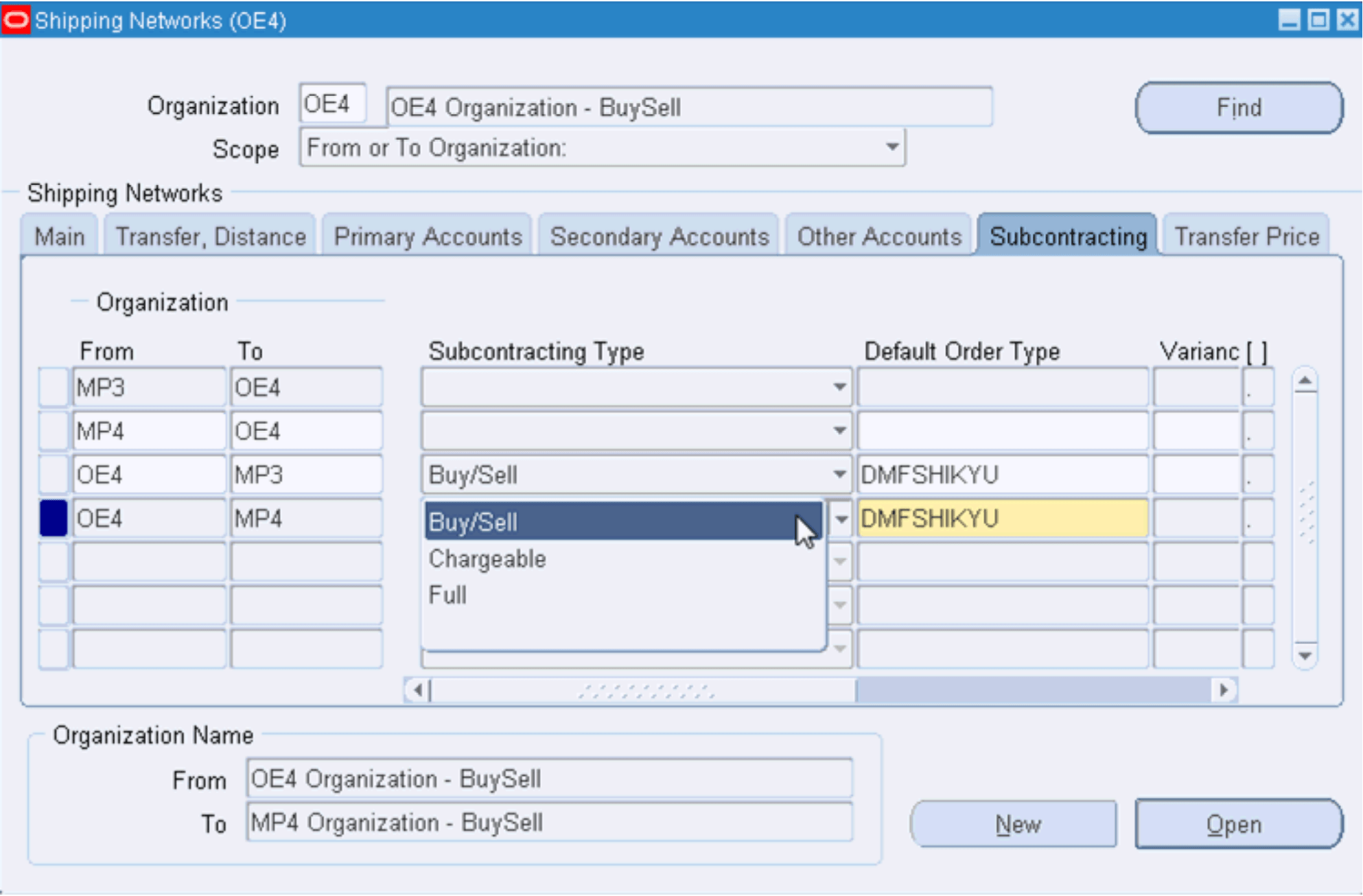

- Define a shipping network to enable material flow from the OEM to the MP, by selecting Full as the Subcontracting Type.

- Select a Variance account to serve as the Subcontracting Intransit account for Full Outsourcing

- Select an Offset account that is used for reducing the outsourced assembly on-hand quantity by miscellaneous issues, and is part of simulation.

Setup Shipping Network for Full Outsourcing

Tips And Considerations

- Actual costing support for Full Outsourcing is only applicable for external manufacturing partners.

- To prevent contamination of actual costs, ensure that users do not create manual transactions in the MP organization. Only automated transactions generated by the application should be permitted.

- The MP organization must be set up to not allow negative balances.

- A separate MP should be defined for every OEM-MP relationship to avoid co-mingling costs from different OEMs

Key Resources

- Oracle E-Business Suite News and Information: oracle.com/ebs

- Oracle E-Business Suite Product Documentation: https://docs.oracle.com/cd/E26401_01/index.htm

- Oracle University: https://www.oracle.com/education

- Oracle Support: https://www.oracle.com/support