Backward Scheduling

When you use the backward scheduling method for production planning, you set the production end date. This is the date you need to have the completed items. Based on data from the associated routing and related work center calendar, NetSuite calculates the time, materials, and resources required to complete all operations. NetSuite determines the production start date and time based on these calculations.

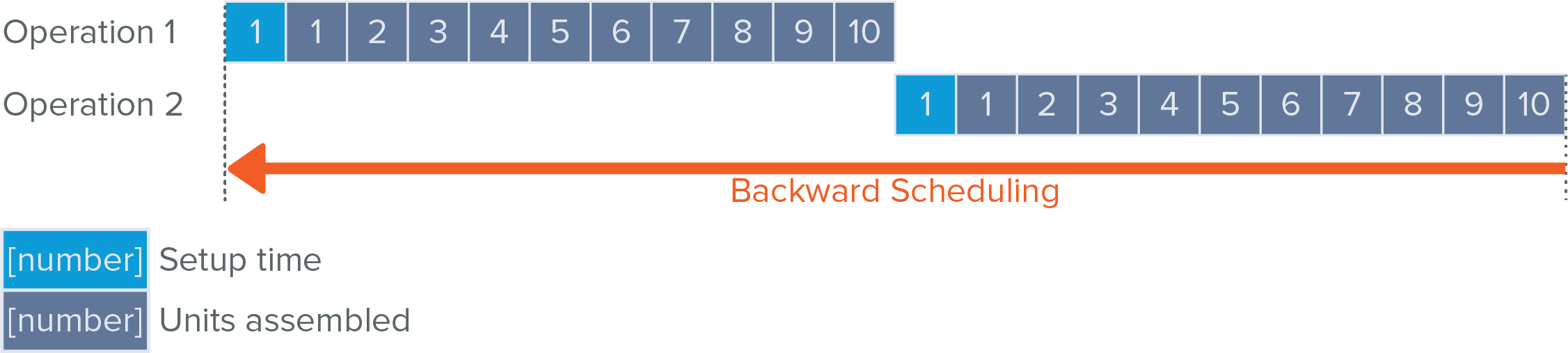

For example, you need to schedule an order of widgets that requires two operations to complete a production run. Each operation requires 1 day of setup time and 10 days of production time. Operation 1 must be complete before Operation 2 can start. These production requirements appear in the following illustration:

When you enter the items completed date, NetSuite calculates the day work must begin to complete production on time. When a work order is created by a supply plan, NetSuite schedules work so that the last operation is completed before the due date. The due date time is 00:01 AM. Therefore, the last operation on the work order is scheduled for completion by 11:59 PM on the day before the due date.

The time displayed for each operation is based on work hours set for each work center. For more information, see Creating Manufacturing Work Centers or Groups.

Planners who use the Backward Scheduling method can reduce waste of manufacturing resources because NetSuite calculates start dates automatically. Work order production is scheduled to start as late as possible, giving planners flexibility to cancel or change an order.

The NetSuite planning engine calculations may set a production start date in the past, depending on the end date entered.

Production work isn't automatically reallocated based on resource capacity. After work orders are created, you may need to assess resource assignments.

When Backward Scheduling is used as the default scheduling method, the production end date on generated work orders is determined using the following factors:

-

Sales Order - The box in the Create WO column on the Items subtab is checked. This is true for an item that uses the WIP multi-step production process. A work order is generated for your assembly item. The production end date on the work order is set to one day before the expected ship date on the work order. If no expected ship date is entered, the production end date is set to the same day as the sales order date.

-

Work Order - The box in the Create WO column on the Items subtab is checked. A work order is generated for a sub-assembly. The sub-assembly's production end date is set to the same date as the parent item's production start date.

-

Supply Plan - A work order is generated during a supply plan. The production end date for a sub-assembly is set to the same date as the parent item's production start date.

Important:The Generate Work Orders in Supply Planning preference must be set to any option except Do not Generate.

-

Mass Creating Work Orders - Reorder point is the Replenishment Method. NetSuite uses Forward Scheduling for the work orders regardless of the default scheduling method set in the account preferences.