Record and Manage Scrap Transactions During Production

You can now record scrap transactions for materials during batch processing, ensuring accurate capture of the scrap quantity and reason.

This feature enables you to:

- Record scrap transactions using a scrap item. The system tracks the scrap quantity in inventory and applies the cost to the product.

- Record scrap transactions for products or ingredients using a new scrap material transaction type. The system applies the cost to the product.

- Analyze scrap costs based on a new source in Oracle Subledger Accounting.

- Maintain full compliance and traceability of scrap using control batch records and electronic records.

This feature gives you better visibility into tracking and analyzing scrap throughout your production processes.

Scrap can now be recorded in two approaches:

- With defined items to track scrap – scrap is managed through predefined inventory items.

- Without defined items to track scrap – scrap is tracked directly against ingredients, products, or by-products without predefined items.

The following scenarios describe how end users will perform scrap-related activities and what system behavior to expect.

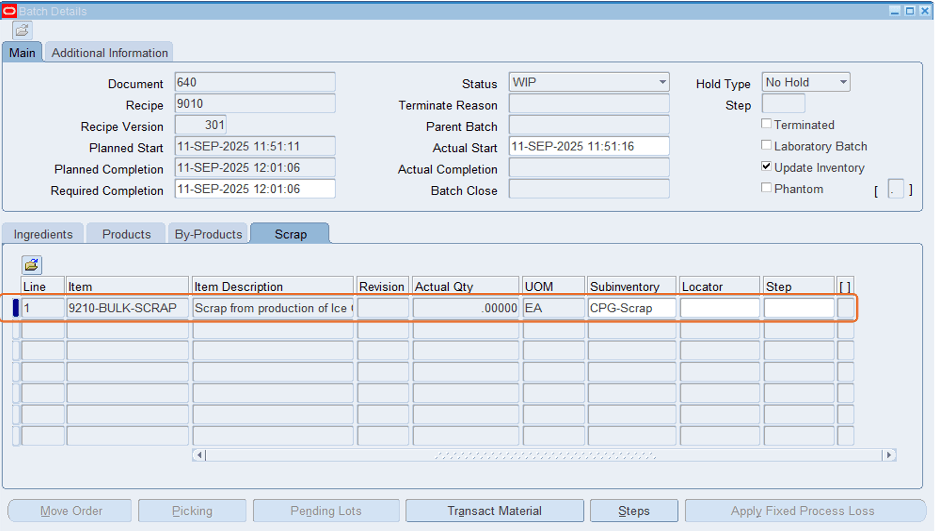

Tracking Scrap Using Predefined Inventory Items

When scrap is managed using predefined inventory items, users add the items to the Scrap tab in Batch Details. A reason code is mandatory for every scrap transaction, and Electronic Signatures (ERES) can be used for compliance. The process differs slightly for lot-controlled and non-lot-controlled items, as described in more detail below.

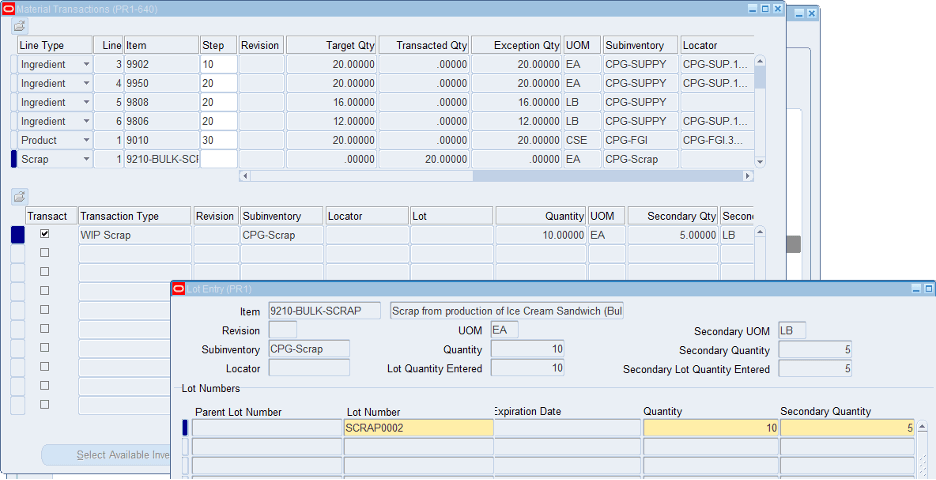

Lot-Controlled Items

For lot-controlled items, the predefined scrap item must first be added to the Scrap tab. The scrap quantity is then recorded through the Material Transactions form. The system requires a valid lot number and other relevant details to ensure full traceability.

After the transaction is posted, the actual scrap quantity in the Scrap tab is updated. Scrap returns are allowed but cannot exceed the quantity originally scrapped

Non-Lot-Controlled Items

Users have two options for recording the scrap quantity: either enter it directly in the Scrap tab or leave it blank and transact later through the Material Transactions form.

- Option 1 - Users can enter the scrap quantity directly in the Scrap tab. This automatically creates the corresponding material transaction and updates inventory and accounting.

- Option 2 – Users can add the scrap item in the Scrap tab without entering a quantity and record the scrap later through the Material Transactions form.

In both cases, scrap returns are allowed but cannot exceed the original scrap quantity, and a reason code is required for all transactions to ensure proper tracking and compliance.

Example: A predefined scrap item is added. The system prompts for quantity and lot information (if applicable), a reason code is entered, and a Material Transaction updates inventory and accounting.

Add Scrap Item

Create Material Transaction

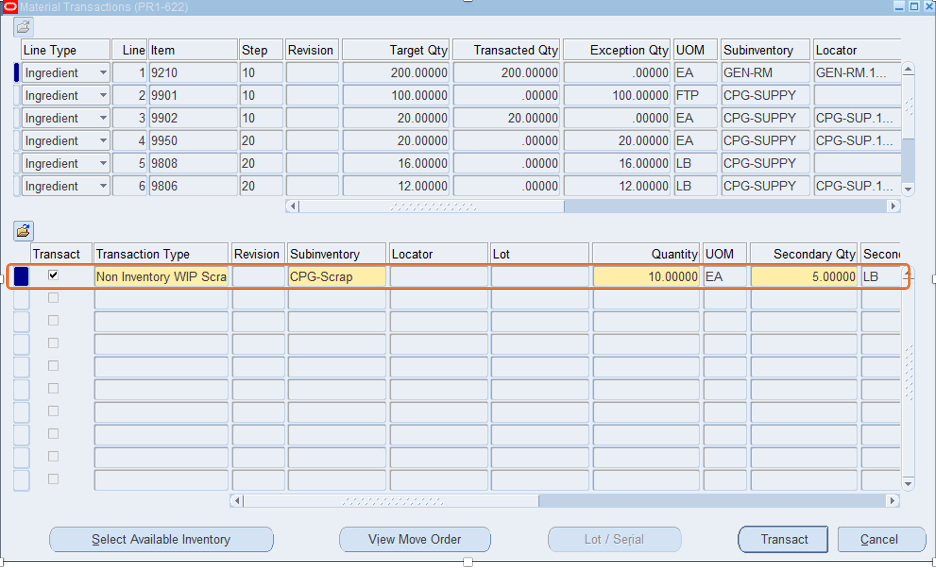

Tracking Scrap Without Predefined Inventory Items

Non-inventory scrap can be recorded directly against batch ingredients, products, or by-products. These transactions do not update inventory and are used for reporting purposes only. A reason code is mandatory, and any corrections must be made via the standard Material Transaction correction process.

For ingredients, scrap can be recorded, but the scrap quantity cannot exceed the transacted quantity Scrap returns can also be recorded but cannot exceed the original scrapped quantity. For products and by-products, scrap quantities can be recorded as needed, and scrap returns are allowed but cannot exceed the original scrapped quantity.

Example: An ingredient scrap is recorded for a batch.

Record Scrap without a Predefined Item

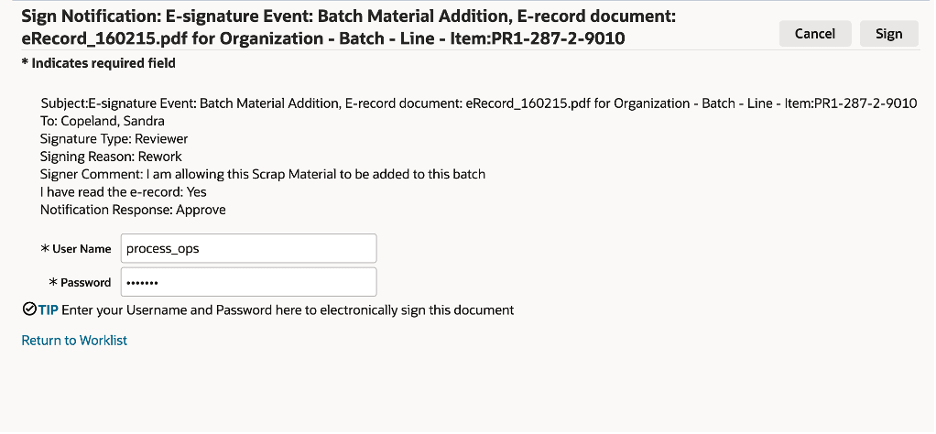

Electronic Signatures (ERES)

Electronic signatures are supported for both inventory and non-inventory scrap transactions, ensuring full compliance and traceability for audits. When enabled, the system prompts for an electronic signature at the time of recording scrap or scrap return.

Example: Users are adding material 9010 as a inventory scrap item to the batch

Sample Electronic Signature

Costing and Accounting

For inventory scrap, the system updates inventory and reduces the batch’s product cost using either standard or actual costing methods. Accounting entries include debiting Scrap Inventory and crediting Work in Process (WIP). Non-inventory scrap does not impact inventory or costing and is used for tracking and reporting only. A new Subledger Accounting (SLA) source, “Scrap Indicator,”, is available to derive accounts for all scrap transactions.

Steps to Enable

You don't need to do anything to enable this feature.